Annular Cutter Set 13 Pcs by, Cutting Depth 1 Cutting Diameter 7/16 to 1-1/16

July 16, 2025

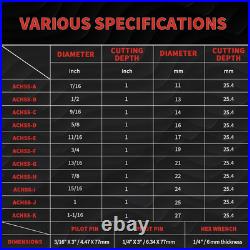

Annular Cutter Set 13 Pcs by, Cutting Depth 1″ Cutting Diameter 7/16″ to 1-1/16 Inch, Mag Drill Bits Kit for Magnetic Drill Press, with 2 Pilot Pins. High Speed Steel (HSS). 10.39 x 10.35 x 3.35 inches; 3.15 Pounds. Annular cutters made with super tough M2AL high speed steel (HSS) for durability, wear resistance, high efficiency and superior service life. 11 HSS core drill bit cutting tool assortment set with Outside Diameter in inches: 7/16″, 1/2″, 9/16″, 11/16″, 5/8″, 3/4″, 13/16″, 7/8″, 15/16″, 1″, 1-1/16,1 inch cutting depth for each drill cutter. CNC-machined high precision annular drill bit set with 3/4 inch Weldon shank (with 2 flats) for secure clamping and edge finish designed for smooth, reamed, burr-free edges of drilled holes. Use a firm steady pressure throughout the cut for best results. IMPORTANT Drill single layers of materials only. This series of annular cutter is NOT designed for drilling of multiple layers. Avoid premature failure of cutter by using a low feed rate when engaging the bit with the work piece, especially for the smaller cutters. Increase to recommended rate once bit is about 2-3mm in. Secure workpiece firmly before drilling. If workpiece is less than 1/2″ thick, use a 3/8″ steel sheet under it to ensure the magnetic drill will grip it firmly. There should be no movement between the workpiece and bit during drilling. Compatible with various brands of magnetic drills including Alfra, BDS, Dewalt, Euroboor, Hougen, Ruko. Caution: if you want to use this annular cutter on a drill press, you need an extra annular cutter arbor for the drill bit cutter. Arbor is not included in this pack. Sturdy good-looking case holding an assortment of 11 annular bits, 2 pilot pins and a bonus hex wrench. Annular Cutter Teeth Detail. Teeth with multi-cut geometry for improved ply cutting and chip removal. 3/4 inch Weldon shank. 2 flat faces for secure clamping. Marks the center of the hole to be cut. Allows the easier flow of lubricant. Ejects the slug out of the metal. For tightening the hex screw in the magnetic drill. MAXIMIZE LIFE OF YOUR ANNULAR CUTTER / PREVENT PREMATURE DULLING OF BLADES. Use our HSS annular cutters to cut suitable materials only. Drill single layers of materials only. This series of annular cutter is designed for single layer drilling only. Recommended for steel sections and steel plate. Can also be used for the materials listed below. For hardened metals, use carbide annular cutters, also available in our store. There should be no movement between the workpiece and drill during cutting. If using a magnetic drill, check there are no metal chips on the magnet base before each cut. They will prevent full magnetic adhesion with the workpiece. If the workpiece is less than 1/2″ thick, use a 3/8″ steel sheet under it to ensure the magnetic drill will grip it firmly. Ensure the correct rpm is used. Consult the above table to use the correct rpm where possible. Use a low feed rate when engaging the annular cutter with the work piece, especially for the smaller bits. Once the cutter is about 2-3mm in, the feed rate can be increased to the recommended rate. Match the annular cutter size and material drilled to the correct feed rate. Recommended speed at which holes should be cut in mm/min =. Feed rate F x Rotation Speed R. As an illustration, using an annular cutter size ½ to drill holes in low carbon steel, the speed at which the hole is cut should be between 0.08 x 612 = 49 mm/min and 0.13 x 612 = 80 mm/min. Adjust the rotation speed of the feed handle to match the recommended speed. We offer the best prices around on high quality products. Our E-store includes media such as books, movies, music and games while offering electronics, toys, sporting apparel, clothing, tools, general home, garden items and more. We are always working hard to ensure your package arrives as soon as possible. We do not accept P. Please provide a physical address. We try our very best to make sure every customer is completely satisfied. If there’s a problem, message us! We’re happy to help.